Waterjet Cutting Foam

Cutting foam manually is very challenging. Since Waterjet exerts no lateral side force on the material being cut, cutting foam with Waterjet is a breeze. There is no distortion or barreling effect on the material. Because of this, Waterjet is a much better method for cutting foam than conventional tools.

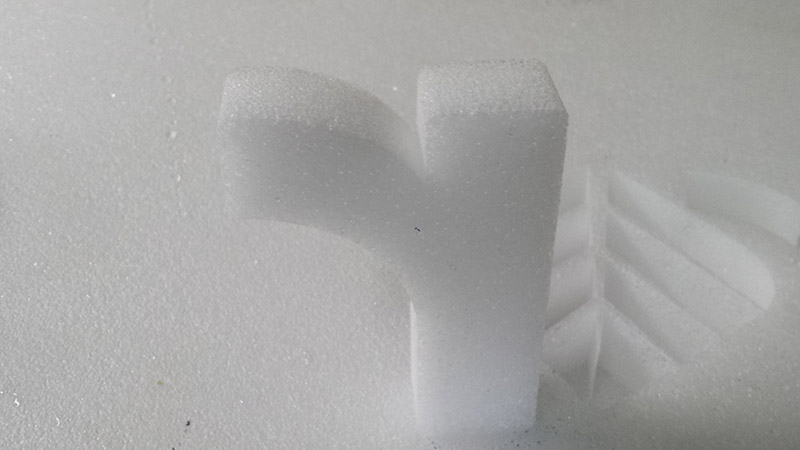

Waterjet cutting of 1” thick foam staked 2 pieces high (total thickness 2”)

Foam is laid out for cutting. With Foam we are able to stack more pieces, and accurately cut multiple sheets at once. Because of this, we can make fewer cuts, saving our customers money in the process.

The finished part. We use sophisticated computer software to ensure precision accurate cuts, for all your professional needs. The applications are endless.

Cutting has been completed and parts removed. Because foam is thinner and porous compared to harder and thicker materials, like metal and glass, we can cut more quickly and very accurately.